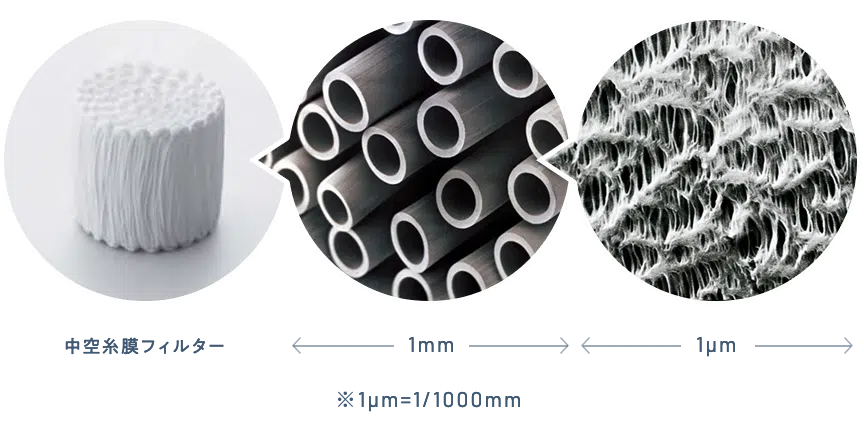

Hollow Fiber Membrane

In the 1970s at a plant of Mitsubishi Rayon (now Mitsubishi Chemical), which was developing fibers for water and blood filtration. The bleaching of polypropylene. when observed under a microscope at the laboratory He noticed that there were countless holes in the walls of the straw-shaped hollow fibers. Adoption has progressed in areas such as wastewater treatment and medical treatment, and in 1978, the world's first oxygen concentrator was introduced.

1974 Successful development of hollow fiber membranes

Microscopic observations at the laboratory of the polypropylene whitening phenomenon occurring at the factory revealed countless holes in the walls of straw-like hollow fibers. Therefore, the researcher at that time thought that it could be used as a "filter membrane" and continued his research. The developed hollow fiber membrane filter has become the cornerstone of other products. followed by many

1978 Developed the world's first hollow fiber oxygen concentrator.

Inspired by the whitening effect of hollow fibers, Mitsubishi Rayon (then) succeeded in developing hollow fiber membrane filters. and offered to various industries used as a filter As a result, the medical industry demands the highest level of functionality and safety. Including the field of wastewater treatment is paying attention. Developed in collaboration with medical device manufacturers. The world's first oxygen concentrator equipped with a hollow fiber membrane was introduced. Later, with the development of hollow fiber polyethylene membranes that can be produced without the use of organic solvents. We therefore seriously enter into the medical water treatment business such as dializers and hand washing equipment.